Biomass Fuels Boiler in Thailand mainly burns solid waste from agriculture and wood processing. Based on the low-carbon economy, power shortage and environmental pollution background, Thailand government made plans to develop clean renewable energy. This passage puts forward the ultimate analysis, proximate analysis and ash fusion point analysis of rice husk, corn cob, bagasse, palm fiber, palm shell, palm oil empty bunch and eucalyptus bark, which provides test data for developing the biomass power generation market in Thailand.

1.1 Ultimate analysis of biomass fuel as received basis

| Fuel type |

C |

H |

O |

N |

S |

Cl |

| Rice husk |

37.51 |

3.83 |

34.12 |

0.29 |

0.03 |

0.20 |

| Corn cob |

13.71 |

0.81 |

35.04 |

0.31 |

0.03 |

0.11 |

| Bagasse |

21.33 |

3.06 |

23.29 |

0.13 |

0.03 |

0.04 |

| Palm fiber |

31.35 |

4.57 |

25.81 |

0.02 |

0.06 |

0.15 |

| Palm shell |

44.44 |

5.01 |

34.73 |

0.28 |

0.02 |

0.02 |

| EFB |

23.38 |

2.74 |

20.59 |

0.35 |

0.10 |

0.13 |

| Eucalyptus bark |

22.41 |

1.80 |

21.07 |

0.16 |

0.01 |

0.13 |

Compared with coal, C content in biomass fuel is lower; H content is similar. O content o is much higher; N and S content is very low. The result shows that the Cl content is quite different, with rice husk 0.20% and palm hull only 0.02%.

1.2 Proximate analysis of biomass fuel

| Fuel type |

Ash |

Moisture |

Volatile |

Fixed carbon |

GCV kJ/kg |

NCV kJ/kg |

| Rice husk |

13.52 |

10.70 |

80.36 |

14.90 |

14960 |

13917 |

| Corn cob |

3.70 |

46.40 |

84.57 |

7.64 |

9638 |

8324 |

| Bagasse |

1.43 |

50.73 |

87.75 |

5.86 |

9243 |

7638 |

| Palm fiber |

6.35 |

31.84 |

78.64 |

13.20 |

13548 |

11800 |

| Palm shell |

3.52 |

12.00 |

80.73 |

16.30 |

18267 |

16900 |

| EFB |

2.04 |

50.80 |

79.30 |

9.76 |

8121 |

6614 |

| Eucalyptus bark |

2.45 |

52.00 |

82.55 |

7.72 |

8487 |

6845 |

Except rice husk, the ash content of rest biomass fuel is as low as less than 10%. Volatile matter of dry ash-free basis is very high, ranging from 78.64% to 87.75%. Rice husk and palm shell have the best ignition characteristics.

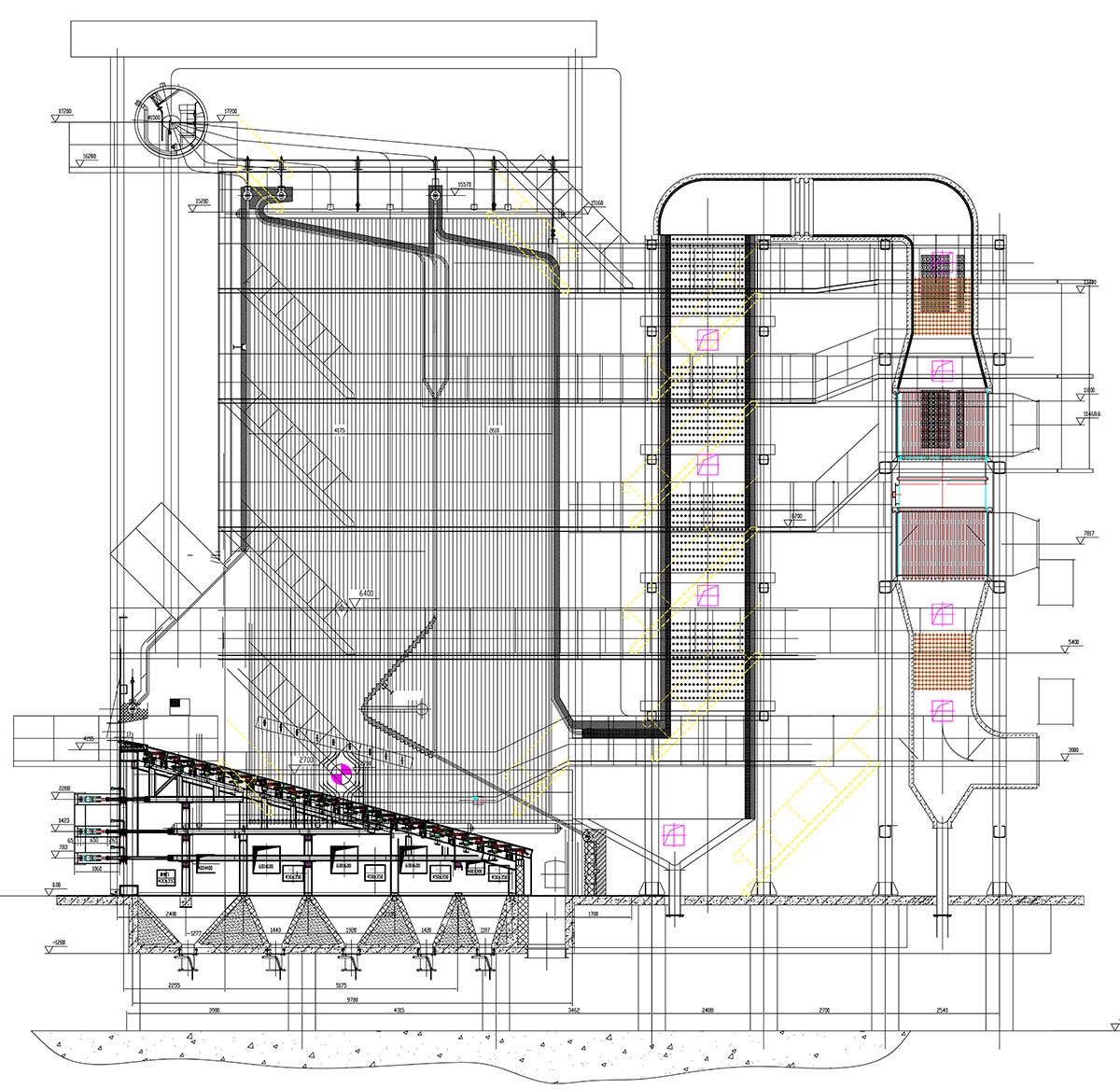

In 2009, biomass boiler manufacturer Taishan Group contracted a power plant boiler burning palm fiber and EFB in Thailand. The biomass fuels boiler is a 35t/h medium temperature and medium pressure step grate boiler. The design mixing ratio of palm fiber to EFB is 35:65. The biomass fuels boiler adopts two-stage hydraulic reciprocating grate to separate the drying area from the combustion area. In the first-stage reciprocating grate, the fuel is radiated by front arch, in which water is driven away. After first-stage reciprocating grate is spreading air, and about 50% of dried fine fibers are blown into the furnace. Rest part falls on second-stage reciprocating grate for combustion. Palm fiber and palm oil empty bunch have strong coking property.

In 2017, we did another 45t/h sub-high temperature and sub-high pressure power plant boiler in Thailand. We improved previous π-shaped layout to new M type layout. The biomass fuels boiler is divided into furnace, cooling chamber and superheater chamber. Upper economizer, primary air preheater, lower economizer and secondary air preheater are in the tail shaft. Ash hoppers are below cooling chamber and superheater chamber to collect fly ash and reduce the risk of superheater coking.

1.3 Analysis of Ash Fusion Characteristics

| Fuel type |

Deformation temperature |

Softening temperature |

Hemispherical temperature |

Flowing temperature |

| Rice husk |

1297 |

1272 |

1498 |

1500 |

| Corn cob |

950 |

995 |

1039 |

1060 |

| Bagasse |

1040 |

1050 |

1230 |

1240 |

| Palm fiber |

1140 |

1160 |

1190 |

1200 |

| Palm shell |

980 |

1200 |

1290 |

1300 |

| EFB |

960 |

970 |

980 |

1000 |

| Eucalyptus bark |

1335 |

1373 |

1385 |

1390 |

The ash fusion point of rice husk is the highest, while corn cob and palm oil empty bunch is the lowest.

1.4 Discussion

High calorific value of rice husk and palm shell increases combustion temperature in furnace and reduces radiant heating surfaces. Due to low moisture content, it can effectively reduce the heat loss due to exhaust gas and improve the thermal efficiency. However, the chlorine in rice husk is high, and volatile KCl is easy to condense and coke in the superheater area. Palm shell has a high calorific value, low ash fusion point and high K content in ash. It is necessary to reasonably adjust the arrangement of combustion and heating surface, or to mix other low calorific value fuels to reduce the flue gas temperature in furnace and superheater.

Corn cob, palm fiber and palm oil empty bunch has high Cl and K, and low ash fusion point. Therefore, the easy-coking area shall adopt alloy steel with strong corrosion resistance (such as TP347H).

Bagasse and eucalyptus bark have higher moisture content, higher heat loss due to exhaust gas and lower thermal efficiency. Arrange reasonable radiant and convective heating surface, increase furnace heating surfaces, and superheater should have sufficient temperature and pressure. It is necessary to choose alloy steel with strong corrosion resistance for superheater.

1.5. Conclusion and Suggestion

(1) Rice husk and palm shell have low moisture, high calorific value, volatile matter and ash melting point, so it can be mixed with other low-grade fuels to improve boiler efficiency.

(2) Corn cob, palm fiber and palm oil empty bunch have high chlorine content and low ash fusion point. The easy-coking area shall adopt alloy steel with strong corrosion resistance.

(3) Bagasse and eucalyptus bark have low calorific value and high ash fusion point, thus the risk of coking in the furnace is low.

Post time: Feb-14-2022