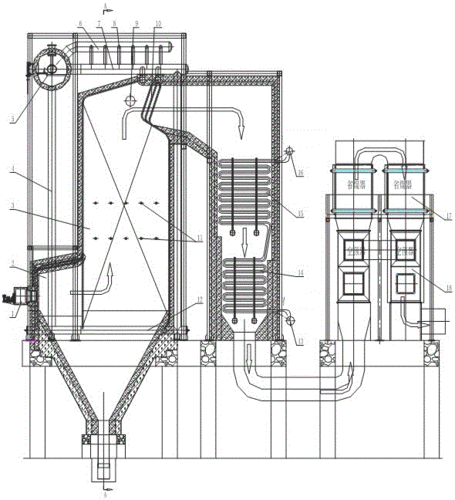

1. Introduction of Coal Slurry Boiler

DHS15-7.5-J coal slurry boiler is a single drum natural circulation corner tube boiler. The boiler drum is outside and not heated, and the furnace adopts membrane wall. The evaporation heating surface is composed of flag surface, membrane wall and close pitched tube. The rear is two-stage economizer and two-stage air preheater. The front wall is with two burners, and ignition adopts light oil. The boiler has a large-angle slag hopper and adopts a water-sealed scraper conveyor.

2. Technical parameters of Coal Slurry Boiler

|

No |

Item |

Value |

|

1 |

Boiler capacity |

15t/h |

|

2 |

Rated steam pressure |

7.5MPa |

|

3 |

Rated steam temperature |

291.4℃ |

|

4 |

Feed water temperature |

105℃ |

|

5 |

Load range |

50%-100% |

|

6 |

Suitable fuel |

Coal water slurry |

|

7 |

Fuel LHV |

16.735kJ/kg |

|

8 |

Design efficiency |

88% |

|

9 |

Consumption of fuel |

2337kg/h |

|

10 |

Flue gas temperature |

150℃ |

|

11 |

Radiation heating area |

106m2 |

|

12 |

Convection heating area |

83.3 m2 |

|

13 |

Economizer heating area |

284 m2 |

|

14 |

Air preheater heating area |

274 m2 |

|

15 |

Normal water volume |

13.8 m3 |

|

16 |

Max. water volume |

19.2 m3 |

|

17 |

Weight of boiler proper |

52t |

|

18 |

Weight of steel structure |

30t |

|

19 |

Dimension after installation |

9.2mx12.2mx16.5m |

3. Overall structure of Coal Slurry Boiler

The coal water slurry boiler adopts a corner tube structure, that is, two large-diameter downcomers are at the four corners of boiler body as the overall support and main water circulation channel. The whole furnace and drum are stretched upwards. The membrane wall and flag tube are delivered in pieces, while the heating surface and header are assembled in the factory, which greatly reduces the on-site workload.

4. Main components of furnace

The whole furnace is arranged in inverse "L" shape to prolong the residence time of flue gas in the furnace. Top membrane wall and refractory brick on both sides form a stable combustion chamber, which makes water evaporate quickly. Since the calorific value is low, furnace volume heat load is 135kW/m3, which is beneficial to fuel burnout. The heat exchange surface is composed of membrane walls with pitch of 80mm and diameter of φ60×5. Ash hopper over 55° is at the bottom of furnace, thus ash can smoothly fall on the slag remover. Secondary air duct in the middle of furnace forms a low nitrogen combustion air supply system together with burner.

Post time: Mar-01-2022