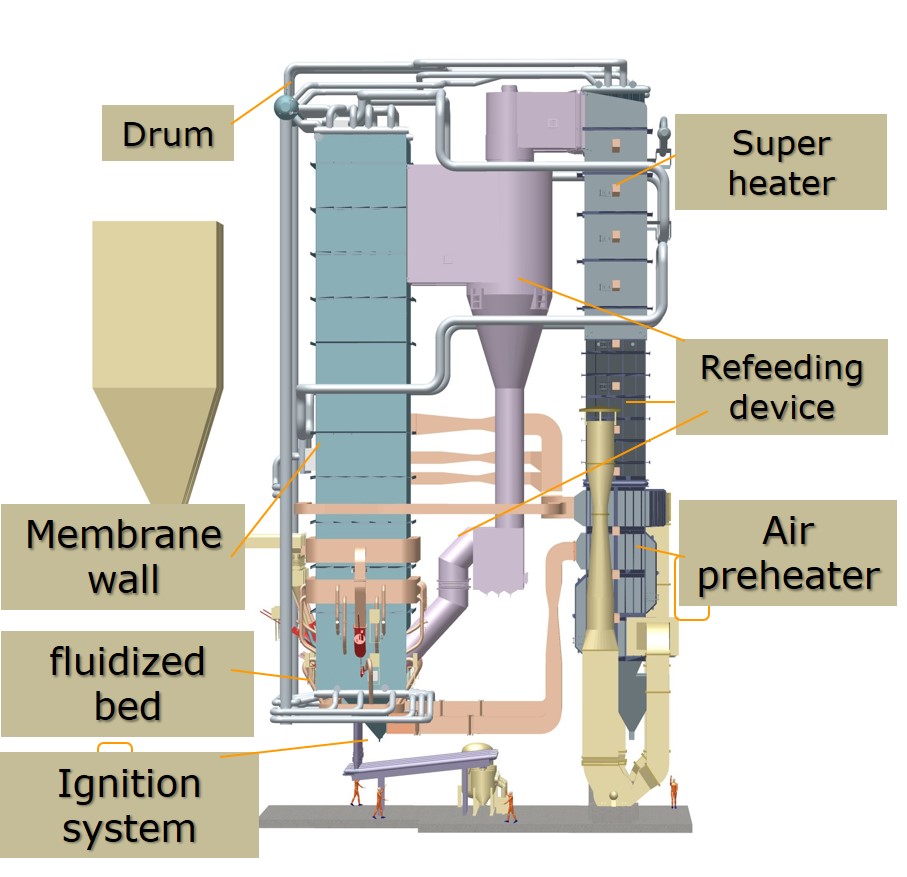

CFB boiler component mainly includes drum, water cooling system, superheater, economizer, air preheater, combustion system and refeeding system. This passage will further introduce each component in detail.

1. Drum, internals and accessory part

(1) Drum: inner diameter is φ1600 mm, thickness is 46mm, shell length is 9400mm, total length is 11360mm; Q345R spherical head.

(2) Internals: single-stage evaporation system with cyclone separator, cleaning orifice and top blinds. It can separate water in steam-water mixture, clean salt in the steam, and balance steam load to ensure steam quality.

(3) Accessory part: dosing tube, emergency water discharge tube and continuous blowdown tube. The drum adopts two U-shaped hangers, and the drum can expand freely towards both ends.

2. Water cooling system

(1) Furnace membrane wall

The furnace cross-sectional size is 8610mm×4530mm, and design flow rate is below 5m/s to improve fuel primary burnout rate. A screen-type evaporation heating surface is in the front upper part. Rigid beams are along the height of membrane wall to increase the furnace rigidity. The working temperature is 870~910℃. The furnace temperature is uniform, which is conducive to the mixing of fuel and limestone, ensuring low nitrogen combustion.

3. Superheater

A convection superheater with spraying desuperheater is in the rear flue duct. The high-temperature superheater is at the top of tail flue duct, in-line arrangement. The low-temperature superheater is at the lower part of high-temperature superheater. One spraying desuperheater is between them to adjust the steam temperature.

2.2.4 Economizer

Economizer is behind the low-temperature superheater.

2.2.5 Air preheater

Air preheater is behind the economizer. The primary and secondary air preheaters are divided into upper, middle and lower tube boxes. Only the last stage air preheater tube box adopts corrosion-resistant 10CrNiCuP (coten tube).

2.2.6 Combustion system

Combustion system mainly includes coal feeder, air distributor, slag remover, secondary air, under-bed ignition burner, etc. Three weighing sealed belt or chain type coal feeders are on the front wall to meet micro-positive pressure combustion. The bell-type hood is evenly arranged on the air distribution plate.

2.2.7 Desulfurization system

The particle size of limestone is generally 0~2mm. Limestone is sprayed into the furnace by a pneumatic conveying system through silo pump. The fuel repeats low-temperature combustion and desulfurization reaction. When the Ca/S ratio is 2~2.2, the desulfurization efficiency can reach 96%, and SO2 emission reaches 100mg/m3 after in-furnace desulfurization.

2.2.8 Denitration system

Two measures to reduce NOx emission: control the oxygen supply during the combustion process; adopt suitable furnace temperature.

2.2.9 Refeeding system

This CFB boiler uses two high-efficiency adiabatic cyclone separators at the furnace outlet.

Post time: Sep-10-2021