Due to the different standard systems in different countries, there are some differences in the boiler performance acceptance test standards or procedures such as European Union standard EN 12952-15:2003, ASME PTC4-1998, GB10184-1988 and DLTT964-2005. This paper focuses on the analysis and discussion of the main differences in boiler efficiency calculation in various standards or regulations.

1. Foreword

Whether at China or abroad, before the boiler is manufactured and installed and handed over to users for commercial operation, the boiler performance test is usually carried out according to the contract, but the standards or procedures of boiler performance test currently used in different countries are not the same. European Union standard EN 12952-15: 2003 Water-tube boiler and auxiliary equipment Part 15 is about the acceptance test standard of boilers, which is one of the widely used boiler performance test standards. This standard is also applicable to circulating fluidized bed boilers. Limestone desulfurization is added to the standard, which is somewhat different from the relevant regulations in China and ASME boiler performance test regulations. The ASME code and related codes in China have been discussed in detail, but there are few reports on the discussion of EN 12952-15: 2003.

At present, the commonly used performance test standards in China are China's national standard (GB) “Power Station Boiler Performance Test Procedures” GB10184-1988 and American society of mechanical engineers's (ASME) “Boiler Performance Test Procedures” ASME PTC 4-1998, etc. With the continuous maturity of China's boiler manufacturing technology, China's boiler products are gradually recognized by the world market. In order to meet the needs of different markets, the European Union standard EN 12952-15: 2003 will not be excluded in the future as the implementation standard for the performance test of boiler products manufactured in China.

The main contents of boiler efficiency calculation in EN12952-15-2003 are compared with ASME PTC4-1998, GB10W4-1988 and DLTT964-2005.

For convenience of comparison, the EN12952-15:2003 standard will be abbreviated as EN standard. ASMEPTC4-1998 code is abbreviated as ASME code, GB10184-1988 code is referred to as GB code for short, DLH'964-2005 is called DI7T for short.

2. Main contents and application scope

EN standard is the performance acceptance standard for steam boilers, hot water boilers and their auxiliary equipment, and it is the basis for the thermal performance (acceptance) test and calculation of steam boilers and industrial boilers that burn directly. It’s suitable for direct combustion steam boilers and hot water boilers, and their auxiliary equipment. The word "direct combustion" is aimed at the equipment with known fuel chemical heat converted into sensible heat, which can have grate combustion, fluidized bed combustion or chamber combustion system. Besides, it can also be applied to indirect combustion equipment (such as waste heat boiler) and equipment running with other heat transfer media (such as gas, hot oil, Sodium), etc. However, it is not suitable for special fuel burning equipment (such as refuse incinerator), pressurized boiler (such as PFBC boiler) and steam boiler in combined cycle system.

Including EN standard, all standards or procedures related to boiler performance test clearly stipulate that it is not applicable to steam generators in nuclear power plants. Compared with ASME code, EN standard can be applied to waste heat boiler and its auxiliary equipment of steam or hot water boiler, and its application scope is wider. EN standard does not limit the applicable range of boiler steam flow, pressure or temperature. as far as steam boilers are concerned, the types of "suitable boilers" listed in EN standard are more explicit than GB code or DL/T code.

3. Boundary of boiler system

ASME code lists the demarcation illustrations of thermal system boundaries of several typical boiler types. Typical illustrations are also given in GB code. According to EN standard, the envelope of conventional boiler system should include the whole steam-water system with circulating pump, combustion system with coal mill (suitable for coal burning system), circulating flue gas blower, fly ash reflux system and air heater. But it does not include oil or gas heating equipment, dust remover, forced draft fan and induced draft fan. EN standard and other regulations basically divide the boundary of boiler thermodynamic system in the same way, but EN standard strongly points out that the formulation of boiler system envelope (boundary) requires that the envelope boundary related to heat balance should be consistent with the boundary of boiler in the "supplied" state, and the heat input, output and loss required for measuring thermal efficiency can be clearly determined. If it is impossible to obtain qualified measured values at the boundary of "supply" status, the boundary can be redefined by agreement between the manufacturer and the purchaser. In contrast, EN standard emphasizes the principle of dividing the boundary of boiler thermodynamic system.

4. Standard state and reference temperature

EN standard defines the state of pressure of 101325Pa and temperature of 0℃ as standard state, and the reference temperature of performance test is 25℃. The specified standard state is the same as GB code; The reference temperature is the same as ASME code.

EN standard allows the agreement to use other temperatures as the reference temperature for acceptance test. When other temperatures are used as reference temperatures, it is necessary to correct the fuel calorific value.

5. Common coefficients

The EN standard gives the specific heat of steam, water, air, ash and other substances in the range from 25℃ to normal operating temperature, and the heat value of some incompletely burned substances.

5.1 specific heat value

See table 1 for partial specific heat value.

Table 1 Specific heat value of some substances.

|

S/N |

Item |

Unit |

Value |

|

1 |

Specific heat of steam in the range of 25℃-150℃ |

kJ(kgK) |

1.884 |

|

2 |

Specific heat of water in the range of 25℃-150℃ |

kJ(kgK) |

4.21 |

|

3 |

Specific heat of air in the range of 25℃-150℃ |

kJ(kgK) |

1.011 |

|

4 |

Specific heat of coal ash and fly ash in the range of 25℃-200℃. |

kJ(kgK) |

0.84 |

|

5 |

Specific heat of large slag in solid slag discharge furnace |

kJ(kgK) |

1.0 |

|

6 |

Specific heat of large slag in liquid slagging furnace |

kJ(kgK) |

1.26 |

|

7 |

Specific heat of CaCO3 in the range of 25℃-200℃ |

kJ(kgK) |

0.97 |

|

8 |

Specific heat of CaO in the range of 25℃-200℃ |

kJ(kgK) |

0.84 |

Like GB code, the enthalpy or specific heat of various substances given by EN standard takes 0℃ as the starting point. ASME code stipulates that 77℉ (25℃) is taken as the starting point for calculating enthalpy or specific heat of various substances except steam enthalpy and fuel oil enthalpy.

In GB code, the specific heat of commonly used substances is calculated according to the calculated temperature through a table or by using a formula, and the obtained specific heat is the average specific calorific value from 0℃ to the calculated temperature. For gaseous substances and water, it is the average specific heat at constant pressure. ASME code generally takes 25℃ as the benchmark, and gives the calculation formula of specific heat or enthalpy of various substances.

Compared with GB code and ASME code, EN standard has the following two differences in determining specific heat of substances:

1) Enthalpy or specific heat of various substances takes 0℃ as the starting point, but the given specific heat value is the average value within the range from 25℃ to the conventional operating temperature.

2) Take the fixed value from 25't℃ to the normal operating temperature.

For example:

| S/N | Item | Unit | Value |

| 1 | Fuel LHV | kJ/kg | 21974 |

| 2 | Flue gas temp. | ℃ | 132 |

| 3 | Slag temp. | ℃ | 800 |

| 4 | The amount of water vapor generated by fuel combustion | N3/kg | 0.4283 |

| 5 | Fuel ash content | % | 28.49 |

| 6 | Ratio of fly ash and slag | 85:15 |

Combined with other parameters, when the reference temperature is 25℃, the results calculated according to GB code and EN standard are compared in Table 2.

Table 2 Comparison of specific heat value and calculated loss of some substances.

|

Item |

Unit |

EN standard |

GB regulations |

| Specific heat of steam in flue gas. |

kJ/(kgK) |

1.884 |

1.878 |

| Specific heat of fly ash |

kJ/(kgK) |

0.84 |

0.7763 |

| Specific heat of bottom slag |

kJ/(kgK) |

1.0 |

1.1116 |

| Loss of steam in flue gas |

% |

0.3159 |

0.3151 |

| Sensible heat loss of fly ash |

% |

0.099 |

0.0915 |

| Sensible heat loss of bottom slag |

% |

0.1507 |

0.1675 |

| Total loss |

% |

0.5656 |

0.5741 |

According to the comparison of calculation results, for the fuel with low ash content, the difference of results caused by different values of specific heat of matter is less than 0.01 (absolute value), which can be considered as having no or little influence on the calculation results, and can be basically ignored. However, when the circulating fluidized bed boiler burns high ash fuel or adds limestone for desulfurization in the furnace, the possible difference of ash heat loss can reach 0.1-0.15 or even higher.

5.2 calorific value of carbon monoxide.

According to EN standard, the calorific value of carbon monoxide is 1 2.633 MJ/m3, which is basically the same as that of ASME code 4347Btu/lbm (12.643 MJ/m3) and GB code 12.636 MJ/m3. Under normal circumstances, the content of carbon monoxide in flue gas is low and the heat loss value is small, so the difference in calorific value has little influence.

5.3 Heat value of incompletely burned substances.

EN standard gives the heat value of incomplete combustion substances in anthracite and lignite fuel ash, as shown in table 3.

Table 3 Heat value of incompletely burned substances.

| Item |

Awarded a position |

Value |

| Anthracite coal |

MJ/kg |

33 |

| Brown coal |

MJ/kg |

27.2 |

According to ASME code, when unburned hydrogen in ash is insignificant, incomplete combustibles can be considered as amorphous carbon, and the calorific value of unburned carbon under this condition should be 33.7MJ/kg. GB code doesn't specify the components of combustible materials in ash, but it is generally considered as unburned carbon. The calorific value of combustible materials in ash given in GB code is 33.727MJ/kg. According to anthracite fuel and EN standard, the calorific value of incomplete combustion substances is about 2.2% lower than ASME code and GB code. Compared with lignite, the difference is even greater.

Therefore, it is necessary to further study the significance of giving calorific values of unburned substances of anthracite and lignite respectively in EN standard.

5.4 Calcination decomposition heat of calcium carbonate and generation heat of sulfate.

According to the calculation formula coefficients given in EN standard, ASME code and DL/T code, the calcination decomposition heat of calcium carbonate and the formation heat of sulfate are shown in Table 4.

Table 4 Heat of decomposition and sulfate formation of calcium carbonate.

|

Item |

Heat of calcium carbonate decomposition kJ/mol. |

Heat of sulfate formation kJ/mol. |

|

EN standard |

178.98 |

501.83 |

|

ASME code |

178.36 |

502.06 |

|

DL/T code. |

183 |

486 |

Coefficients given by EN standard and ASME code are basically the same. Compared with DT/L code, the decomposition heat is 2.2-2.5% lower and the formation heat is about 3.3% higher.

6. Heat loss caused by radiation and convection

According to EN standard, because it is generally impossible to measure the radiation and convection losses (that is, the commonly understood heat dissipation losses), empirical values should be adopted.

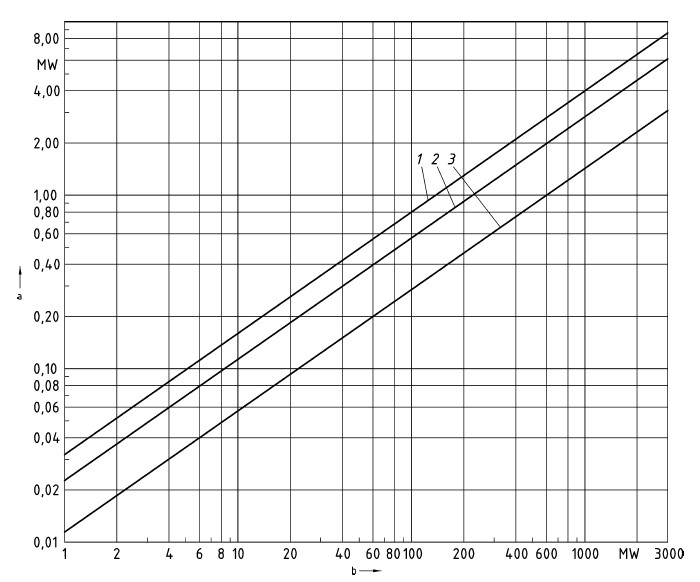

EN standard requires that the design of the most common steam boiler should comply with fig. 1, "radiation and convection losses varying with the maximum effective heat output".

Fig. 1 Radiation and convection loss lines

Key:

a: radiation and convection losses;

B: maximum useful heat output;

Curve 1: brown coal, blast furnace gas and fluidized bed boiler;

Curve 2: hard coal boiler;

Curve 3: fuel oil and natural gas boilers.

Or calculated according to formula (1):

Qrc=CQn0.7 ( 1 )

Type:

C = 0.0113, suitable for oil-fired and natural gas boilers;

0.022, suitable for anthracite boiler;

0.0315, suitable for lignite and fluidized bed boilers.

According to the definition of effective heat output in EN standard, the effective heat output is the total heat of feed water and/or steam transmitted by steam boiler, and the enthalpy of sewage is added to the effective heat output.

For example:

| S/N | Item | Unit | Value |

| 1 | Capacity under the boiler BMCR | t/h | 1025 |

| 2 | Steam temp. | ℃ | 540 |

| 3 | Steam pressure | MPa | 17.45 |

| 4 | Feed water temp. | ℃ | 252 |

| 5 | Feed water pressure | MPa | 18.9 |

Combined with other parameters, the maximum effective heat output of the boiler is about 773 MW, and the radiation and convection loss is 2.3MW when burning anthracite, that is, the radiation and convection heat loss is about 0.298%. Compared with the heat dissipation loss of 0.2% under the rated load of the boiler body calculated according to the example parameters in GB code, the radiation and convection loss calculated or valued according to EN standard is about 49% higher.

It should be added that EN standard also gives calculation curves or formula coefficients according to different furnace types and fuel types. ASME code requires that the heat loss be estimated by measurement, but "parameter estimation given by professional qualified personnel is not excluded". GB code roughly gives the calculation curve and formula according to the unit and boiler body.

7. Flue gas loss

Flue gas loss mainly includes dry flue gas loss, loss caused by water separation in fuel, loss caused by hydrogen in fuel and loss caused by moisture in air. According to the calculation idea, ASME standard is similar to GB code, that is, dry flue gas loss and water vapor loss are calculated separately, but ASME calculates according to mass flow rate, while GB calculates according to volume flow rate. EN standard calculates wet flue gas quality and specific heat of wet flue gas as a whole. It should be emphasized that for boilers with air preheater, the flue gas quantity and temperature in EN standard and GB code formulas are the flue gas quantity and temperature at the outlet of air preheater, while those in ASME code formulas are the flue gas quantity at the inlet of air preheater and the flue gas temperature at the outlet of preheater when the air leakage rate of air preheater is corrected to 0. See table 5 for calculation examples of EN and GB. from table 5, it can be seen that although the calculation methods are different, the calculation results are basically the same.

Table 5 Comparison of flue gas exhaust loss calculated by GB and EN.

| S/N | Item | Symbol | Unit | GB | EN |

| 1 | Received base carbon | Car | % | 65.95 | 65.95 |

| 2 | Received base hydrogen | Har | % | 3.09 | 3.09 |

| 3 | Received base oxygen | Oar | % | 3.81 | 3.81 |

| 4 | Received base nitrogen | Nar | % | 0.86 | 0.86 |

| 5 | Received base sulfur | Sar | % | 1.08 | 1.08 |

| 6 | Total moisture | Mar | % | 5.30 | 5.30 |

| 7 | Received base ash | Aar | % | 19.91 | 19.91 |

| 8 | Net calorific value | Qnet,ar | kJ/kg | 25160 | 25160 |

| 9 | Carbon dioxide in flue gas | CO2 | % | 14.5 | 14.5 |

| 10 | Oxygen content in flue gas | O2 | % | 4.0 | 4.0 |

| 11 | Nitrogen in flue gas | N2 | % | 81.5 | 81.5 |

| 12 | Datum temperature | Tr | ℃ | 25 | 25 |

| 13 | Flue gas temperature | Tpy | ℃ | 120.0 | 120.0 |

| 14 | Specific heat of dry flue gas | Cp.gy | kJ/m3℃ | 1.357 | / |

| 15 | Specific heat of steam | CH2O | kJ/m3℃ | 1.504 | / |

| 16 | Specific heat of wet flue gas. | CpG | kJ/kgK | / | 1.018 |

| 17 | Heat loss of dry flue gas. | q2gy | % | 4.079 | / |

| 18 | Heat loss of steam | q2rM | % | 0.27 | / |

| 19 | Heat loss of flue gas | q2 | % | 4.349 | 4.351 |

8. Efficiency correction

As it is usually impossible to carry out the unit performance acceptance test under the standard or guaranteed fuel conditions and under the precise standard or guaranteed operating conditions, it is necessary to correct the test results to the standard or contract operating conditions. All three standards/regulations put forward their own methods for correction, which have both similarities and differences.

8.1 revised items.

All three standards have corrected the inlet air temperature, air humidity, exhaust gas temperature at the boundary exit and fuel, but GB code and ASME code have not corrected the ash in fuel, while EN standard has deduced and calculated the correction of ash change in fuel in detail.

8.2 correction method.

The revision methods of GB code and ASME code are basically the same, which are to replace the revised parameters with the original calculation formula of loss items and recalculate them to obtain the revised loss value. The amendment method of EN standard is different from GB code and ASME code. EN standard requires that the equivalent difference δ a between design value and actual value should be calculated first, and then the loss difference δ n should be calculated according to this difference. the loss difference plus the original loss is the corrected loss.

8.3 Fuel composition changes and correction conditions.

GB code and ASME code do not limit the change of fuel in performance test, as long as both parties reach an agreement. The DL/T supplement increases the allowable variation range of the test fuel, and EN standard puts forward clear requirements for the variation range of moisture and ash in the fuel, which requires that the deviation of yHO from the guaranteed value of water in the fuel should not exceed 10%, and the deviation of yAsh from the guaranteed value should not exceed 15% before correction. At the same time, it is stipulated that if the test deviation exceeds the range of each deviation, the performance acceptance test can only be carried out after an agreement is reached between the manufacturer and the user.

8.4 Fuel calorific value correction.

GB and ASME code do not specify the correction of fuel calorific value. EN standard emphasizes that if the agreed reference temperature is not 25℃, the fuel calorific value (NCV or GCV) should be corrected to the agreed temperature. the correction formula is as follows:

Ha: net calorific value of fuel at reference temperature of 25℃;

Hm: fuel net calorific value corrected according to the agreed reference temperature tr.

9. Test error and uncertainty

Including boiler performance test, any test may have errors. Test errors are mainly composed of systematic errors, random errors, and errors of omission, etc. All three standards require that possible errors should be evaluated and eliminated as much as possible before the test. ASME Code and EN Standard put forward according to the concepts of uncertainty and uncertainty.

According to GB test content, the measurement error and analysis error of each measurement and analysis item are calculated, and the final efficiency calculation error is obtained to judge whether the test is qualified.

It is stipulated in relevant chapters of ASME Code that all parties to the test should determine the acceptable values of the uncertainty of the test results before the test, and these values are called the target uncertainty of the results. ASME Code provides the calculation method of the uncertainty. The ASME code also stipulates that after each test is completed, the uncertainty must be calculated according to the relevant chapters of the code and ASME PTC 19.1 code. If the calculated uncertainty is greater than the target uncertainty reached in advance, the test will be invalid. ASME Code emphasizes that the uncertainty of the calculated test results is not the allowable error limit of boiler performance, and these uncertainties are only used to judge the level of performance test (i.e. whether the test is effective or not), rather than to evaluate the boiler performance.

EN standard stipulates that the final relative efficiency uncertainty eηB shall be calculated according to the uncertainty of each sub-item, and then the efficiency uncertainty uη β shall be calculated according to the following formula:

UηΒ=ηΒXεηΒ

If the following conditions are met, it shall be deemed that the guaranteed value of efficiency is achieved:

ηΒg≤ηB+UηΒ

In which:

η g is the guarantee value of efficiency;

ηB is the corrected efficiency value.

It can be clearly seen from the above discussion that the error analysis of GB and the calculation of uncertainty in ASME code are the criteria for judging whether the test is successful, which has nothing to do with whether the efficiency index is qualified, while the uncertainty in EN standard does not judge whether the test is successful, which is closely related to whether the efficiency index is qualified.

10. Conclusion

GB10184-88, DL/T964-2005, ASME PTC4-1998 and EN12592-15:2003 clearly stipulate the boiler efficiENcy test and calculation method, which makes the boiler performance acceptance based on evidence. GB and ASME codes are widely used in China, while en standards are rarely used in domestic acceptance.

The main idea of boiler performance evaluation test described by the three standards is the same, but due to the different standard systems, there are differences in many details. This paper makes some analysis and comparison of the three standards, which is convenient to use the standards of different systems more accurately in project acceptance. EN standard has not been widely used in China, but it is necessary to make a deeper analysis and research on some of its provisions. To make technical preparations in this respect, promote the export of domestic boilers to a country or region that implements the EU standard, and improve our adaptability to the international market.

Post time: Dec-04-2021