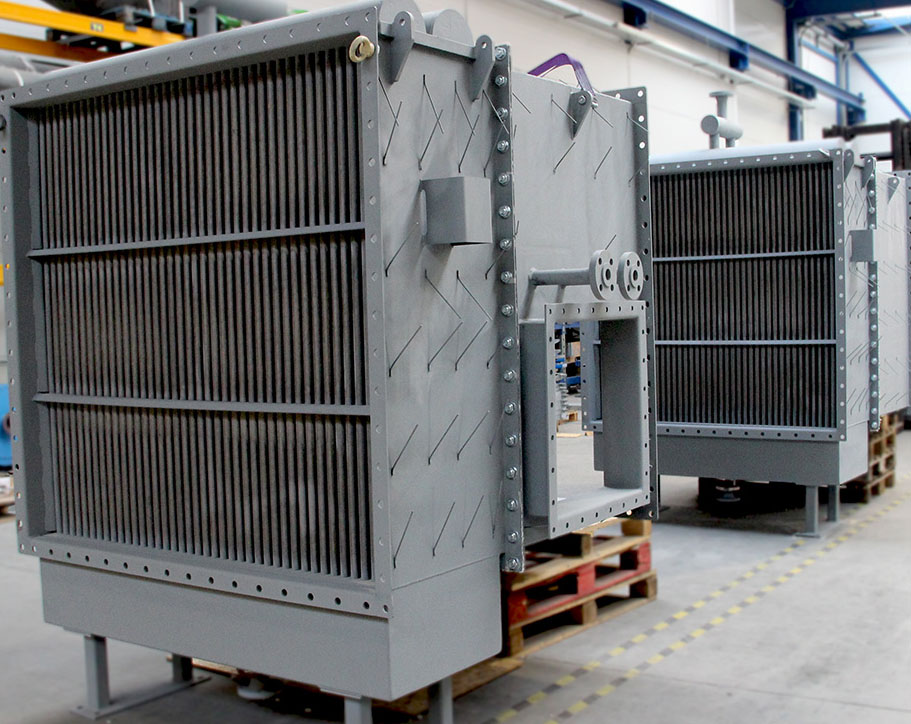

Steam Air Preheater is replacing conventional flue gas air preheater in most waste incineration power plant boiler in China. There is large amount of acid gases like HCI and SO2 in the flue gas of waste incineration boiler, which can cause ash deposition and low-temperature corrosion in the tail flue duct. Therefore, the power of ID fan increases, the service life of air preheater shortens, and boiler operation. stability reduces. Due to high water content in waste, we use high-temperature air to dry waste, which can improve the combustion efficiency.

At present, most steam air preheaters in China adopt two-stage type. The primary air from garbage storage pit is heated to 160°C by low-pressure steam extracted from steam turbine; and then heated to 220°C by high-pressure saturated steam from boiler drum. The condensed water goes to the deaerator through the drainage pipe. Reasonable steam air preheater system and operating parameters can effectively improve the operation economy of garbage incineration boiler.

1. Thermal analysis of two-stage steam air preheater

1.1 Extract the saturated steam from high-pressure steam drum.

Heat of high-temperature air preheater comes from drum saturated steam in part, and the rest from heat with condensed water. Saturated steam comes from boiler inside, which reduces the output heat of boiler. The air returns to furnace to support combustion, which circulates inside the boiler and utilizes the heat. Since the condensed water temperature is higher than feed water temperature, it can only enter feed water system after cooling.

2.2 Extraction low-pressure steam from steam turbine

One part of extraction heat preheats low-temperature air, and the rest is the heat of condensed water. The steam extracted from turbine comes outside of boiler, which increases the output heat of boiler.

2. Optimization of steam air preheater

Add one flash tank at the outlet of high-pressure condensed water, and the low-pressure condensed water joins the flash tank drainage. Add one condensed water section before the low-pressure section to preheat air.

Three-stage steam air preheater increases the heat exchange from flash tank and condensed water section. It utilizes the heat of high-temperature condensed water, reduces heat loss, and also improves operation safety of steam air preheater.

Post time: Mar-26-2022