18 Years Factory Biomass Fuel Hot Oil Boiler - SZL Biomass Boiler – Taishan Group

18 Years Factory Biomass Fuel Hot Oil Boiler - SZL Biomass Boiler – Taishan Group Detail:

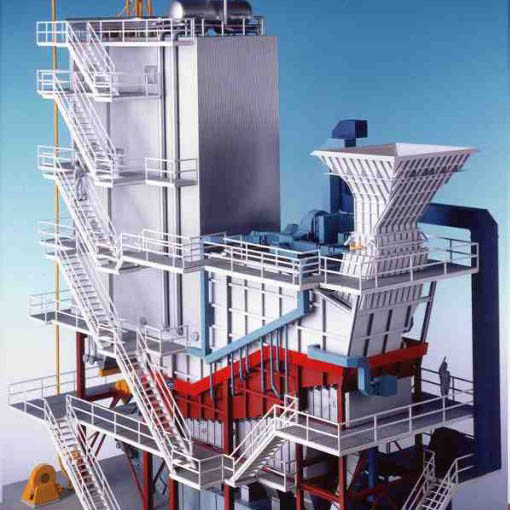

SZL Biomass Boiler

Product Description

SZL series biomass boiler adopts chain grate, which is suitable for burning the biomass fuel like wood chip, biomass pellet, etc. SZL series biomass boiler is double drum natural circulation boiler, the whole into an "O" -shaped arrangement, use of chain grate. The front of boiler is the rising flue duct, that is, the furnace; its four walls are covered with membrane wall tube. The rear of boiler is arranged convection bank. The economizer is arranged outside the boiler.

Similar to coal fired boiler, SZL series biomass boiler also has the characteristics of big heating surface, high thermal efficiency, little fuel leakage, separate air chamber, sufficient burning, variable frequency control, PLC automatic control. SZL series biomass fired boilers can generate low pressure steam with rated evaporation capacity of 6-35 ton/h and rated pressure of 0.7-2.5 MPa. The designed thermal efficiency is up to 82%.

Features:

1. The overall structural arrangement is compact and reasonable, the structure form and water circulation circuit is simple and clear, the boiler structure is compact, covering small area, nice appearance and less civil engineering investment.

2. The boiler is easy to operate, smooth operation, rapid temperature and pressure rise, output capacity is sufficient, suitable for a wide range of fuel.

3. Boiler achieves the interlock protection of water supply, feeding, grate running, slag removal, FD & ID control, overpressure, high & low water level, ensure the safe operation of the boiler. Equipped with a complete thermal monitoring instrument and electronic control operating floor. FD & ID fan start and grate speed adjustment can be automatically operated. The boiler is equipped with overpressure alarm and water level automatic adjustment.

4. The reasonable arrangement of front and rear arch forms a strong radiation arch, strengthening the combustion, and increasing the fuel adaptability. Light chain grate with a speed adjustment device, which has a wide adjustment range of speed.

5. The arrangement of sufficient heating surface ensures a reasonable flue gas temperature and improves the thermal efficiency. Boiler output capacity is sufficient, convection heating surface heat transfer efficiency is high, can reach the rated output and has 10% overload capacity.

6. Boiler furnace adapts to the combustion characteristics of biomass fuels, use of high furnace, the furnace wall is surrounded by the membrane wall, reasonable arrangement of front and rear arch, fuel can be completely burned in the furnace to reduce the fly ash loss and improve the radiant heating capacity.

Application:

SZL series biomass fired boilers are widely used in chemical industry, paper making industry, textile industry, food industry, pharmaceuticals industry, heating industry, construction industry.

| Technical Data of SZL Biomass Steam Boiler | ||||||||

| Model | Rated Evaporation Capacity (t/h) | Rated Steam Pressure (MPa) | Feed Water Temperature (°C) | Rated Steam Temperature (°C) | Radiation Heating Area (m2) | Convection Heating Area (m2) | Economizer Heating Area (m2) | Active Grate Area (m2) |

| SZL4-1.25-SW | 4 | 1.25 | 20 | 193 | 11.7 | 101 | 33.1 | 4.7 |

| SZL6-1.25-SW | 6 | 1.25 | 105 | 193 | 18.7 | 121 | 104.64 | 7.64 |

| SZL6-1.6-SW | 6 | 1.6 | 105 | 204 | 18.7 | 121 | 104.64 | 7.64 |

| SZL6-2.5-SW | 6 | 2.5 | 105 | 226 | 18.7 | 121 | 104.64 | 7.64 |

| SZL8-1.25-SW | 8 | 1.25 | 105 | 193 | 29.2 | 204.1 | 191 | 8.27 |

| SZL8-1.6-SW | 8 | 1.6 | 105 | 204 | 29.2 | 204.1 | 191 | 8.27 |

| SZL8-2.5-SW | 8 | 2.5 | 105 | 226 | 29.2 | 204.1 | 191 | 8.27 |

| SZL10-1.25-SW | 10 | 1.25 | 105 | 193 | 46.3 | 219 | 246 | 10 |

| SZL10-1.6-SW | 10 | 1.6 | 105 | 204 | 46.3 | 219 | 246 | 10 |

| SZL10-2.5-SW | 10 | 2.5 | 105 | 226 | 46.3 | 219 | 246 | 10 |

| SZL15-1.25-SW | 15 | 1.25 | 105 | 193 | 48.8 | 241 | 283 | 13.5 |

| SZL15-1.6-SW | 15 | 1.6 | 105 | 204 | 48.8 | 241 | 283 | 13.5 |

| SZL15-2.5-SW | 15 | 2.5 | 105 | 226 | 48.8 | 241 | 283 | 13.5 |

| SZL20-1.25-SW | 20 | 1.25 | 105 | 193 | 65.6 | 286 | 326 | 18.9 |

| SZL20-1.6-SW | 20 | 1.6 | 105 | 204 | 65.6 | 286 | 326 | 18.9 |

| SZL20-2.5-SW | 20 | 2.5 | 105 | 226 | 65.6 | 286 | 326 | 18.9 |

| Remark | 1. Design thermal efficiency is 82%. | |||||||

Product detail pictures:

Related Product Guide:

Our business aims to operating faithfully, serving to all of our clients , and working in new technology and new machine continuously for 18 Years Factory Biomass Fuel Hot Oil Boiler - SZL Biomass Boiler – Taishan Group , The product will supply to all over the world, such as: Florence , Peru , San Diego , Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work whole-heartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!