Free sample for Coal Fired Boiler For Glove Line - DHL Coal Fired Boiler – Taishan Group

Free sample for Coal Fired Boiler For Glove Line - DHL Coal Fired Boiler – Taishan Group Detail:

DHL Coal Fired Boiler

Product Description

DHL series boiler is single drum horizontal chain grate bulk boiler. The burning part adopts flake chain grate to match with high-quality auxiliary equipment and perfect automatic control system, which ensures safe, stable and efficient operation of boiler.

DHL series coal fired boilers are designed and optimized for applications to produce low, medium and high pressure steam or hot water with rated evaporation capacity from 10 to 65 ton/hr and rated pressure from 1.25 to 9.8 MPa. The design heat efficiency of DHL coal boilers is up to 81~82%.

Features:

1. High efficiency, low fuel consumption; low operating costs

2. High safety level, panel-type heating surface in the furnace, furnace heated evenly.

3. Improve the furnace temperature field to ensure safe operation of the boiler

4. Reasonable flue gas speed, heating surface without ash deposition and no abrasion, under the condition of no soot-blowing, the boiler can work full-load, high-efficiency and safety in long term.

5. The big and tall boiler furnace can be designed according to the different fuel to improve the burning rate of fuel and remove black smoke.

6. All independent loop and reasonable coal boiler injected circulation are specially designed and adopted for the hot water boilers. The medium speed in loop of heat surface is higher than national standard.

7. Environmental protection effect is good, use multi-level dust removal, reduce exhaust gas concentration, Ringelmann blackness is less than 1.

Application:

DHL series coal fired boilers are widely used in chemical industry, paper making industry, textile industry, food industry, pharmaceuticals industry, heating industry, construction industry.

| Technical Data of DHL Coal Fired Hot Water Boiler | ||||||||||

| Model | Rated Thermal Power (MW) | Rated Output Pressure (MPa) | Rated Output Temperature (°C) | Rated Input Temperature (°C) | Radiation Heating Area (m²) | Convection Heating Area (m²) | Air Preheater Heating Area (m²) | Active Grate Area (m²) | Flue Gas Temperature (°C) | Installation Dimension (mm) |

| DHL29-1.6/130/70-AII | 29 | 1.6 | 130 | 70 | 195 | 640 | 275 | 34.4 | 153 | 12600x11200x15000 |

| DHL46-1.6/130/70-AII | 46 | 1.6 | 130 | 70 | 296 | 786 | 624 | 57.2 | 150 | 14600x13600x15000 |

| DHL58-1.6/130/70-AII | 58 | 1.6 | 130 | 70 | 361 | 1181 | 804 | 70.9 | 159 | 13200x15000x17000 |

| DHL64-1.6/130/70-AII | 64 | 1.6 | 130 | 70 | 371 | 1556 | 1450 | 78.27 | 147 | 13800x15000x17000 |

| DHL70-1.6/130/70-AII | 70 | 1.6 | 130 | 70 | 474 | 1488 | 901 | 87.8 | 150 | 14200x17000x17600 |

| Remark | 1. DHL coal fired hot water boilers are suitable for all types of coals. 2. Design thermal efficiency is 82~84%. | |||||||||

| Technical Data of DHL Coal Fired Steam Boiler | ||||||||||||||

| Model | Rated Evaporation Capacity (t/h) | Rated Steam Pressure (MPa) | Feed Water Temperature (°C) | Rated Steam Temperature (°C) | Radiation Heating Area (m2) | Slag Screen Heating Area (m2) | Superheater Heating Area (m2) | Convection Heating Area (m2) | Economizer Heating Area (m2) | Air Preheater Heating Area (m2) | Active Grate Area (m2) | Coal Consumption (kg/h) | Flue Gas Temperature (℃) | Installation Dimension (mm) |

| DHL35-3.82-AII | 35 | 3.82 | 105 | 450 | 152 | 35.4 | 271 | 630 | 693.3 | 31.4 | 6310 | 143 | 14500x10500x14900 | |

| DHL65-1.6-AII | 65 | 1.6 | 105 | 204 | 421.4 | 1085.1 | 826 | 410.3 | 63 | 7792 | 152 | 18000x15300x15000 | ||

| DHL65-3.82-AII | 65 | 3.82 | 150 | 450 | 293 | 59 | 510 | 923 | 1179 | 61.34 | 10940 | 160 | 16500x13400x16000 | |

| Remark | 1. Design thermal efficiency is 81~82%. 2. Heat efficiency and coal consumption is calculated by LHV 19845KJ/Kg (4740kcal/kg). | |||||||||||||

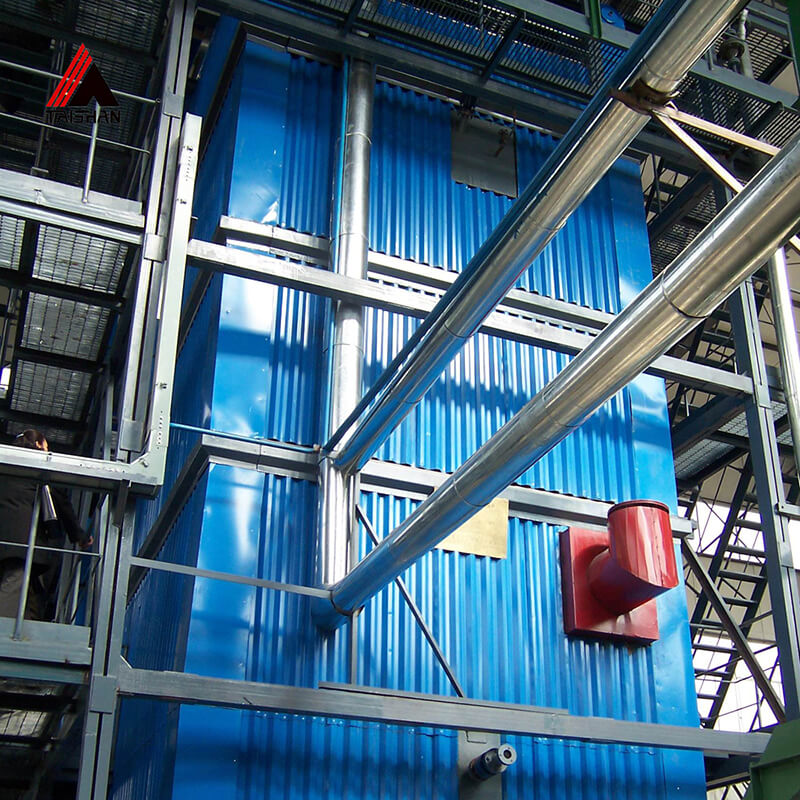

Product detail pictures:

Related Product Guide:

With a sound business credit, excellent after-sales service and modern manufacturing facilities, we have earned an excellent reputation among our customers across the world for Free sample for Coal Fired Boiler For Glove Line - DHL Coal Fired Boiler – Taishan Group , The product will supply to all over the world, such as: Berlin , Mexico , Paraguay , Insisting over the high-quality generation line management and prospects guide provider, we have made our resolution to offer our shoppers using the initially stage purchasing and soon after provider working experience. Preserving the prevailing helpful relations with our prospects, we even now innovate our product lists the many time to meet up with the brand new wants and stick to the latest trend of this business in Ahmedabad. We're ready to facial area the difficulties and make the transform to grasp many of the possibilities in international trade.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.