OEM China Burn Garbage In Incinerator - Garbage Incinerator – Taishan Group

OEM China Burn Garbage In Incinerator - Garbage Incinerator – Taishan Group Detail:

Garbage Incinerator

Main disposal method of municipal solid waste includes incineration, composting, and landfill. Incineration is the most effective method, realizing the goal of harmlessness, reduction and resource utilization. After incineration, it can eliminate a lot of harmful germs and toxic substances. After incineration, the volume can be reduced by more than 90%; the weight can be reduced by more than 80%; the generated heat energy can be used for power generation and heat supply. The incineration method features large processing capacity, high speed, and small floor area. Due to the superiority of the incineration method, garbage incinerator has become an important way of waste disposal in recent years.

Technical characteristics of garbage incinerator

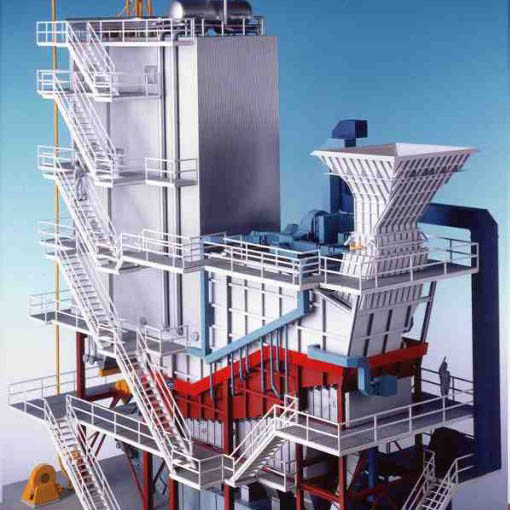

1. It adopts single drum natural circulation vertical or horizontal arrangement, with superheater, spray type desuperheater, primary and secondary air preheater and economizer.

2. The cold air is fed from the bottom of the furnace and blown out from the gap of the grate, which has a good cooling effect on the grate.

3. The falling of the garbage makes it fully flipped and stirred, which ensures that all garbages are exposed to the combustion air and fully burned.

4. The segmented adjustment of the grate makes the control of the combustion condition is more convenient.

5. Easy, stable and reliable operation. Wide fuel adaptability ensures that most of the solid waste can be directly burned in the furnace without any pretreatment.

6. Furnace arch and combustion chamber design as well as air layout and distribution are suitable for the low calorific value and high moisture of urban garbage.

7. The furnace adopts a full-membrane wall structure, so the sealing effect is more reliable.

8. The convective heating surface adopts appropriate flue gas speed and anti-friction cover, and the center distance of the pipe is properly arranged to avoid the tube bundle being blocked by fly ash.

| Technical Data of Garbage Incinerator | ||||||

| Garbage incineration capacity (ton/day) |

Rated Evaporation Capacity (t/h) | Rated Steam Pressure (MPa) |

Feed Water Temperature (°C) |

Rated Steam Temperature (°C) |

Flue gas Temperature (°C) |

Structure type |

| 200 | 15 | 2.5 | 105 | 400 | 14.8 | Vertical |

| 250 | 19 | 2.5 | 105 | 400 | 42 | Vertical |

| 300 | 23 | 2.5 | 105 | 400 | 62.65 | Vertical |

| 350 | 27 | 4 | 130 | 400 | 190 | Horizontal |

| 400 | 31 | 4 | 130 | 400 | 190 | Horizontal |

| 450 | 35 | 4 | 130 | 400 | 190 | Horizontal |

| 500 | 39 | 4 | 130 | 400 | 190 | Horizontal |

| 550 | 43 | 4 | 130 | 400 | 190 | Horizontal |

| 600 | 47 | 4 | 130 | 400 | 190 | Horizontal |

| 800 | 63 | 4 | 130 | 400 | 190 | Horizontal |

| Note | 1. Design thermal efficiency is 81%. 2. Heat efficiency is calculated by LHV 6280KJ/Kg(1500kcal/kg). | |||||

Product detail pictures:

Related Product Guide:

We're commitment to offer you the aggressive cost ,superb products and solutions top quality, too as fast delivery for OEM China Burn Garbage In Incinerator - Garbage Incinerator – Taishan Group , The product will supply to all over the world, such as: Roman , Cyprus , Riyadh , Over the years, with high-quality products, first- class service, ultra-low prices we win thee trust and favor of customers. Nowadays our products sell all over the domestic and abroad. Thanks for the regular and new customers support. We provide high quality product and competitive price, welcome the regular and new customers cooperate with us!

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.