OEM manufacturer Dzl Coal Fired Steam Boiler - SHL Coal Fired Boiler – Taishan Group

OEM manufacturer Dzl Coal Fired Steam Boiler - SHL Coal Fired Boiler – Taishan Group Detail:

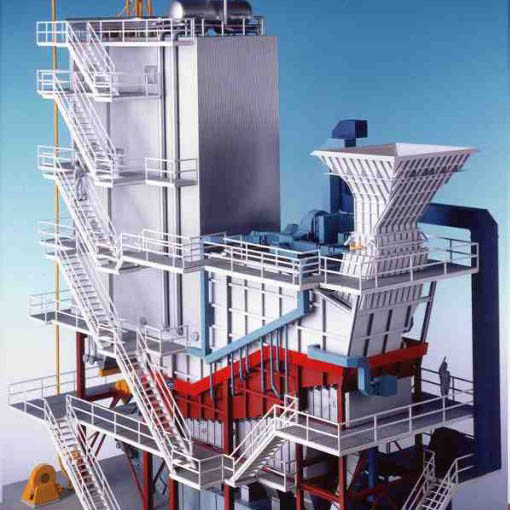

SHL Coal Fired Boiler

Product Description

SHL series boiler is double drum horizontal chain grate bulk boiler, rear part sets air preheater. The burning equipment adopts flake chain grate to match high-quality auxiliary machine, attachment and perfect automatic control equipment, which ensures safe, stable economical and efficient running of boiler.

SHL series coal fired boilers are specially designed and optimized for applications to produce low, medium and high pressure steam or hot water with rated evaporation capacity from 10 to 75 ton/hr and rated pressure from 1.25 to 3.82 MPa. The design heat efficiency of SHL coal boilers is up to 81~82%.

Features:

1) The outlet power of boiler is enough; design efficiency is high.

2) The boiler adopts flake chain grate, without coal leakage, heat loss of fuel is little.

3) The wind chamber is independent and sealed.

4) The air pre-heater is installed at the rear heat surface, which reduces the outlet smoke temperature and rises the boiler feeding air temperature, promote timely and full burning of the fuel.

5) The outlet of furnace sets slag proof tube, which avoids slag-bonding of convection tubes, improves the heat transfer effect.

6) Convection tubes sets guide plates for flue gas, which guides the smoke to scour the tube and improve heat transfer coefficient.

7) Inspection door and observation door are convenient for maintenance; soot-blowing port may clean out the soot formation.

8) Water feeding and coal feeding is automatic, overpressure and overtemperature interlock protection ensures safe operation of the boiler.

Application:

SHL series coal fired boilers are widely used in chemical industry, paper making industry, textile industry, food industry, pharmaceuticals industry, heating industry, construction industry.

| Technical Data of SHL Coal Fired Steam Boiler | ||||||||||||

| Model | Rated Evaporation Capacity (t/h) | Rated Steam Pressure (MPa) | Feed Water Temperature (°C) | Rated Steam Temperature (°C) | Radiation Heating Area (m2) | Convection Heating Area (m2) | Economizer Heating Area (m2) | Air Preheater Heating Area (m2) | Active Grate Area (m2) | Coal Consumption (kg/h) | Flue Gas Temperature (℃) | Installation Dimension (mm) |

| SHL10-1.25-AII | 10 | 1.25 | 105 | 193 | 42 | 272 | 94.4 | 170 | 12 | 1491 | 155 | 12000x7000x10000 |

| SHL15-1.25-AII | 15 | 1.25 | 105 | 193 | 62.65 | 230.3 | 236 | 156.35 | 18 | 2286 | 159 | 13000x7000x10000 |

| SHL20-1.25-AII | 20 | 1.25 | 105 | 193 | 70.08 | 434 | 151.16 | 365.98 | 22.5 | 2930 | 150 | 14500x9000x12500 |

| SHL20-2.5/400-AII | 20 | 2.5 | 105 | 400 | 70.08 | 490 | 268 | 365.98 | 22.5 | 3281 | 150 | 14500x9000x12500 |

| SHL35-1.25-AII | 35 | 1.25 | 105 | 193 | 135.3 | 653.3 | 316 | 374.9 | 34.5 | 4974 | 144 | 17000x10000x12500 |

| SHL35-1.6-AII | 35 | 1.6 | 105 | 204 | 135.3 | 653.3 | 316 | 379.9 | 34.5 | 5007 | 141 | 17000x10000x12500 |

| SHL35-2.5-AII | 35 | 2.5 | 105 | 226 | 135.3 | 653.3 | 273.8 | 374.9 | 34.5 | 5014 | 153 | 17000x10000x12500 |

| SHL40-2.5-AII | 40 | 2.5 | 105 | 226 | 150.7 | 736.1 | 253.8 | 243.7 | 35 | 5913 | 148 | 17500x10500x13500 |

| SHL45-1.6-AII | 45 | 1.6 | 105 | 204 | 139.3 | 862.2 | 253.8 | 374.9 | 40.2 | 6461 | 157 | 17500x10500x13500 |

| SHL75-1.6/295-AIII | 75 | 1.6 | 105 | 295 | 309.7 | 911.7 | 639.7 | 1327.7 | 68.4 | 10163 | 150 | 17000x14500x16400 |

| Remark | 1. SHL coal fired steam boilers are suitable for all types of coals. 2. Design thermal efficiency is 81~82%. 3.Heat efficiency and coal consumption is calculated by LHV 19845KJ/Kg (4740kcal/kg). | |||||||||||

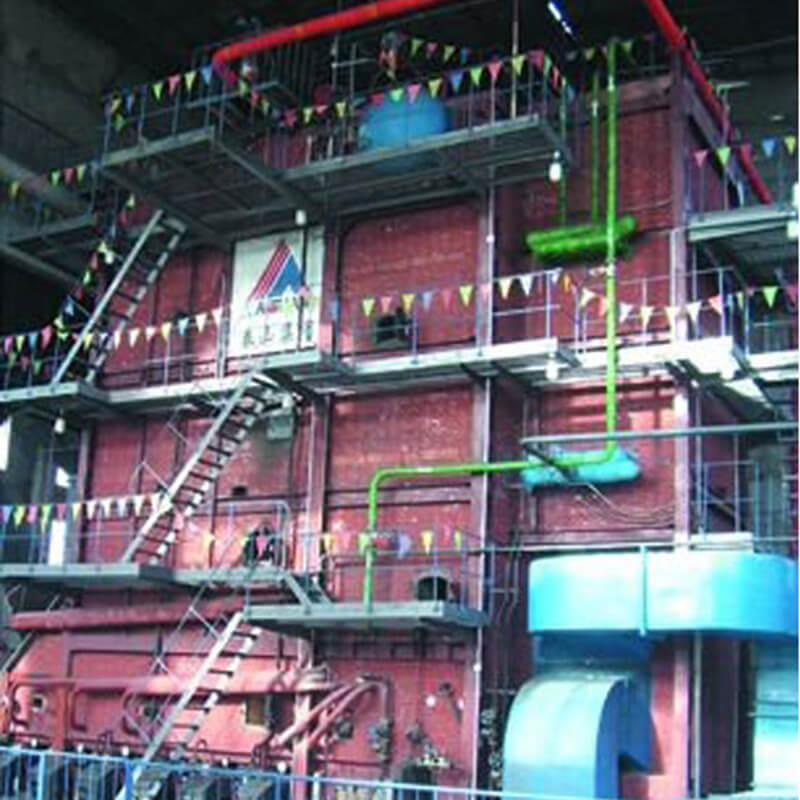

Product detail pictures:

Related Product Guide:

We goal to understand excellent disfigurement from the manufacturing and supply the top support to domestic and abroad clients wholeheartedly for OEM manufacturer Dzl Coal Fired Steam Boiler - SHL Coal Fired Boiler – Taishan Group , The product will supply to all over the world, such as: Swiss , Bangladesh , Argentina , Our technical expertise, customer-friendly service, and specialized products make us/company name the first choice of customers and vendors. We are looking for your inquiry. Let's set up the cooperation right now!

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.