OEM/ODM Supplier Thermal Oil Boiler for Plywood Plant - WNS Gas Fired Boiler – Taishan Group

OEM/ODM Supplier Thermal Oil Boiler for Plywood Plant - WNS Gas Fired Boiler – Taishan Group Detail:

WNS Oil Fired Boiler

Product Description

WNS series gas fired steam boiler is three-pass full wet back structure, adopting large furnace and thick smoke pipe to increase the heat absorption of the furnace and effectively save energy and reduce consumption. The threaded pipe and corrugated furnace greatly enhance the heat transfer effect and greatly save fuel consumption. The main structure includes: boiler shell, ripple furnace, reversal chamber, thread smoke tube, etc. The burner brand can be chosen according to user' s requirement.

WNS series gas fired steam boiler is designed and optimized to produce low pressure steam or hot water with rated evaporation capacity from 1 to 20 ton/hour and rated pressure from 0.7 to 1.6MPa. The design heat efficiency is up to 95%.

Features:

1. There is more heating surface to spare to assure running of full load and overcharge.

2. The boilers are matched with imported burner of European brand. Proportional control, procedure ignition, automatic blowing and flameout protective device. The burning efficiency is over 99.5%.

3. The furnace shape is fit for the shape of flame, avoiding the flame washing out the heating surface area.

4. The temperature of rear flue chamber is low so that the operators feel comfortable and safe.

5. Boiler adopts light quality thermal insulation material: aluminum silicate fiber, good heat preservation, less heat lost, high heating efficiency.

6. The automatic control box adopts full automatic operating to actualize auto-igniting and auto-outage. And it also has manual switch.

7. The automatic control protection procedure has full functions, such as automatic blowing, fuel gas leak alarm, safe operating interlock protection, flameout protection, fuel gas pressure protection.

8. Boiler set the explosion-proof gate to keep safe.

9. Boiler is packaged leaving the factory, installed and adjusted in local.

Application:

WNS series gas fired steam boiler is widely used in chemical industry, paper making industry, textile industry, food industry, pharmaceuticals industry, heating industry, construction industry.

| Technical Data of WNS Gas Fired Hot Water Boiler | ||||||||||

| Model | Rated Thermal Power (MW) | Rated Output Pressure (MPa) | Rated Output Temperature (°C) | Rated Input Temperature (°C) | Heating Area (m²) |

Furnace volume (m³) | Flue Gas Temperature (°C) | Fuel Consumption (m³/h) | Max Transport Weight (Ton) | Max Transport Dimension (mm) |

| WNS0.7-0.7/95/70-Q | 0.7 | 0.7 | 95 | 70 | 18.5 | 0.7 | 161 | 77 | 4.5 | 3130x1600x2040 |

| WNS1.4-0.7/95/70-Q | 1.4 | 0.7 | 95 | 70 | 42.7 | 1.4 | 155 | 156 | 7.2 | 4100x2100x2434 |

| WNS1.4-1.0/95/70-Q | 1.4 | 1 | 95 | 70 | 42.7 | 1.4 | 155 | 154 | 7.2 | 4100x2100x2434 |

| WNS2.1-1.0/95/70-Q | 2.1 | 1 | 95 | 70 | 63.2 | 2.5 | 140 | 234 | 8.9 | 4765x2166x2580 |

| WNS2.8-0.7/95/70-Q | 2.8 | 0.7 | 95 | 70 | 84.3 | 2.5 | 140 | 311 | 9.1 | 4765x2166x2580 |

| WNS2.8-1.0/95/70-Q | 2.8 | 1 | 95 | 70 | 84.3 | 2.5 | 140 | 311 | 9.1 | 4765x2166x2580 |

| WNS4.2-0.7/95/70-Q | 4.2 | 0.7 | 95 | 70 | 132.1 | 4.7 | 162 | 463 | 9.1 | 5570x2400x2714 |

| WNS4.2-1.0/95/70-Q | 4.2 | 1 | 95 | 70 | 132.1 | 4.7 | 162 | 467 | 12.9 | 5570x2400x2714 |

| WNS4.2-1.0/115/70-Q | 4.2 | 1 | 115 | 70 | 132.1 | 4.7 | 162 | 467 | 12.9 | 5570x2400x2714 |

| WNS5.6-1.0/95/70-Q | 5.6 | 1 | 95 | 70 | 153.3 | 5.4 | 163 | 624 | 18.6 | 6490x2910x3230 |

| WNS5.6-1.0/115/70-Q | 5.6 | 1 | 115 | 70 | 153.3 | 5.4 | 163 | 617 | 18.6 | 6000x2645x3053 |

| WNS7-1.0/95/70-Q | 7 | 1 | 95 | 70 | 224.6 | 6.2 | 163 | 770 | 21.3 | 6620x2700x3374 |

| WNS7-1.0/115/70-Q | 7 | 1 | 115 | 70 | 224.6 | 6.2 | 163 | 770 | 21.3 | 6334x2814x3235 |

| WNS10.5-1.0/95/70-Q | 10.5 | 1 | 95 | 70 | 281 | 11.8 | 155 | 1159 | 30.3 | 7644x3236x3598 |

| WNS10.5-1.25/115/70-Q | 10.5 | 1.25 | 115 | 70 | 281 | 11.8 | 155 | 1155 | 30.3 | 7644x3236x3598 |

| WNS14-1.0/95/70-Q | 14 | 1 | 95 | 70 | 390.8 | 16.8 | 160 | 1531 | 31.4 | 7850x3500x3500 |

| WNS14-1.25/115/70-Q | 14 | 1.25 | 115 | 70 | 390.8 | 16.8 | 160 | 1534 | 31.4 | 7850x3500x3500 |

| WNS14-1.6/130/70-Q | 14 | 1.6 | 130 | 70 | 390.8 | 16.8 | 160 | 1550 | 31.4 | 8139x3616x3640 |

| Remark | 1. Design efficiency is 92~95%. 2. LHV is based on 35588KJ/Nm3. | |||||||||

| Technical Data of WNS Gas Fired Steam Boiler | ||||||||||

| Model | Rated Evaporation Capacity (t/h) | Rated Steam Pressure (MPa) | Rated Steam Temperature (°C) | Feed Water Temperature (°C) | Heating Area (m²) |

Furnace volume (m³) | Flue Gas Temperature (°C) | Fuel Consumption (m³/h) | Max Transport Weight (t) | Max Transport Dimension (mm) |

| WNS1-0.7-Q | 1 | 0.7 | 170 | 20 | 21.52 | 0.74 | 157 | 81 | 4.9 | 3540x1926x2212 |

| WNS1-1.0-Q | 1 | 1 | 184 | 20 | 21.52 | 0.74 | 165 | 82 | 4.9 | 3540x1926x2212 |

| WNS2-0.7-Q | 2 | 0.7 | 170 | 20 | 49.72 | 1.47 | 158 | 162 | 8.4 | 4220x2215x2540 |

| WNS2-1.0-Q | 2 | 1 | 184 | 20 | 49.72 | 1.47 | 138 | 162 | 8.4 | 4220x2215x2540 |

| WNS2-1.25-Q | 2 | 1.25 | 193 | 20 | 49.72 | 1.47 | 144 | 162 | 8.4 | 4220x2215x2540 |

| WNS3-1.25-Q | 3 | 1.25 | 193 | 20 | 71.86 | 2.16 | 163 | 246 | 10.3 | 4807x2308x2634 |

| WNS4-1.0-Q | 4 | 1 | 184 | 20 | 99.62 | 2.85 | 158 | 323 | 12.3 | 5610×2410×2720 |

| WNS4-1.25-Q | 4 | 1.25 | 193 | 20 | 99.62 | 2.85 | 160 | 323 | 12.3 | 5610×2410×2720 |

| WNS4-1.6-Q | 4 | 1.6 | 204 | 20 | 99.62 | 2.85 | 167 | 324 | 12.3 | 5610×2410×2720 |

| WNS6-1.0-Q | 6 | 1 | 184 | 105 | 149.22 | 3.89 | 152 | 418 | 15.1 | 5962×2711×3034 |

| WNS6-1.25-Q | 6 | 1.25 | 193 | 105 | 149.22 | 3.89 | 167 | 419 | 15.1 | 5962×2711×3034 |

| WNS6-1.6-Q | 6 | 1.6 | 204 | 105 | 149.22 | 3.89 | 167 | 420 | 15.1 | 5962×2711×3034 |

| WNS8-1.0-Q | 8 | 1 | 184 | 105 | 186.33 | 5.1 | 155 | 556 | 20.3 | 6500x2930x3200 |

| WNS8-1.25-Q | 8 | 1.25 | 193 | 105 | 186.33 | 5.1 | 165 | 560 | 20.3 | 6500x2930x3200 |

| WNS8-1.6-Q | 8 | 1.6 | 204 | 105 | 186.33 | 5.1 | 169 | 562 | 20.3 | 6500x2930x3200 |

| WNS10-1.25-Q | 10 | 1.25 | 193 | 105 | 218.63 | 5.8 | 157 | 694 | 21.9 | 6420x2930x3360 |

| WNS10-1.6-Q | 10 | 1.6 | 204 | 105 | 218.63 | 5.8 | 168 | 712 | 21.9 | 6420x2930x3360 |

| WNS15-1.25-Q | 15 | 1.25 | 193 | 105 | 285.9 | 11.6 | 170 | 1050 | 35 | 7500x3250x3700 |

| WNS15-1.6-Q | 15 | 1.6 | 204 | 105 | 285.9 | 11.6 | 166 | 1057 | 35 | 7500x3250x3700 |

| WNS20-1.25-Q | 20 | 1.25 | 193 | 105 | 440 | 16 | 164 | 1391 | 43.2 | 8160x3680x3750 |

| WNS20-1.6-Q | 20 | 1.6 | 204 | 105 | 440 | 16 | 165 | 1401 | 43.2 | 8160x3680x3750 |

| Remark | 1. Design efficiency is 92~95%. 2. LHV is based on 35588KJ/Nm3. | |||||||||

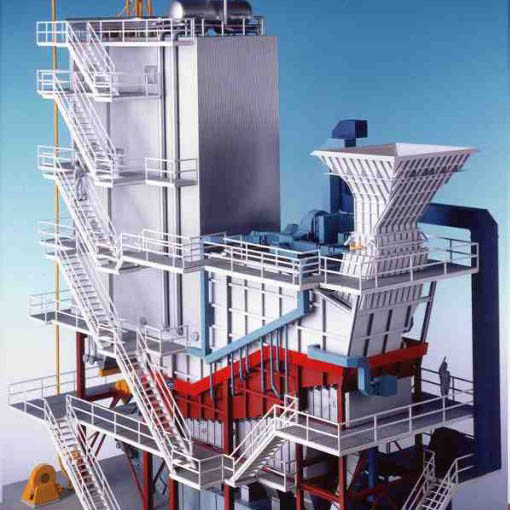

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and repair consciousness, our corporation has won an excellent reputation amongst customers all around the entire world for OEM/ODM Supplier Thermal Oil Boiler for Plywood Plant - WNS Gas Fired Boiler – Taishan Group , The product will supply to all over the world, such as: Singapore , Guinea , Cyprus , With more and more Chinese products around the world, our international business is developing rapidly and economic indicators big increase year by year. We have enough confidence to offer you both better products and service, because we are more and more powerful, professional and experience in domestic and international.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!