Boiler Drum is the most important equipment in boiler equipment, and plays a connecting role. When water becomes qualified superheated steam in a boiler, it has to go through three processes: heating, vaporization and overheating. Heating from feed water to saturated water is a heating process. Vaporizing saturated water into saturated steam is a vaporization process. Heating saturated steam into superheated steam is a superheating process. Above three processes are completed by economizer, evaporation heating surface and superheater respectively. The boiler drum receives the water from economizer and forms a circulation loop with evaporation heating surface. Saturated steam shall be distributed to superheater by steam drum.

Role of boiler drum

1. Energy storage and buffering effect: a certain amount of water and steam are stored in the steam drum, which has an energy storage effect. When the load changes, it can buffer the imbalance between the evaporation amount and water supply amount and rapid change of steam pressure.

2. Ensuring steam quality: steam drum has steam-water separation device and steam cleaning device, which can ensure steam quality.

Brief introduction of boiler drum

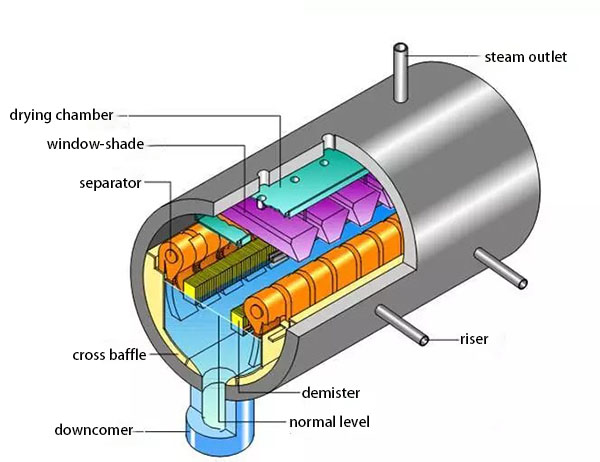

(1). The steam drum and heat exchanger are connected by riser and downcomer to form water circulation. The drum water cycle is a convective heat cycle. Steam drum receives the feed water from feed water pump, and delivers saturated steam to superheater, or directly outputs steam.

(2) There is a steam-water separation device and a continuous blowdown device to ensure boiler steam quality.

(3) It has certain heat storage capacity; when the boiler operating conditions change, it can slow down the rate of change of steam pressure.

(4) There are pressure gauges, water level gauges, accident water discharge, safety valves and other equipment to ensure safe boiler operation.

(5) The steam drum is a balance container providing the pressure required for the flow of steam-water mixture in the water wall.

Structure of boiler drum

The steam drum mainly includes three parts:

(1) Steam-water separation device.

(2) Steam cleaning device.

(3) Blowdown, dosing, and accidental water discharge.

Safety valve on boiler drum

The steam drum has two safety valves, and the setting pressures are different. The safety valve with low setting value controls superheated steam, while the one with high setting value controls the drum pressure.

Blowdown of boiler drum

Continuous blowdown and periodic blowdown are for steam drum blowdown.

(1) Continuous blowdown is mainly used to discharge the concentrated water at the upper part of the drum. Main purpose is to prevent boiler water from containing too much salt and sulfur. The blowdown location is at 200-300mm below the drum water level.

(2) Periodic blowdown is intermittent blowdown; the water slag from the bottom of boiler is blowdown once every 8-24 hours. Each time it lasts for 0.5-1 minute, and the blowdown rate is not less than 1%. The intermittent blowdown should be frequent and short-term.

Dosing of boiler frum

Na3PO4 is diluted and pumped into the boiler water in the boiler drum by dosing pump. Adding trisodium phosphate into boiler water can not only make calcium and magnesium generate non-caking loose water slag, but also correct the alkalinity of the water, so as to keep the PH value within the range specified by the regulations.

Post time: Oct-25-2021