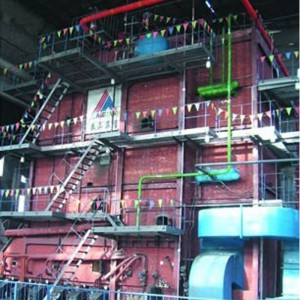

DHS Pulverized Coal Boiler

Product Description

DHS series pulverized coal fired steam boiler is the third generation of energy-saving and environment-friendly industrial pulverized coal boiler, which has the advantage of high efficiency, environmental protection, energy saving, and strong coal applicability. The pulverized coal is burnt in the furnace, and the high-temperature flue gas enters the lime desulfurization unit and bag filter. The clean flue gas is discharged into the atmosphere through the chimney, and the fly ash collected by the bag filter is discharged through a closed system for centralized treatment and utilization.

Features:

(1) Concentrated supply of pulverized coal: the pulverized coal is uniformly supplied by the milling plant, and the quality is stable.

(2) Friendly working environment: the whole system is closed, automatic pulverized coal feeding, concentrated ash discharge, and no dust running.

(3) The operation is simple: the system can realize the immediate starting and stopping.

(4) High efficiency and energy saving: pulverized coal combustion is sufficient, boiler heat transfer effect is good, air excess coefficient is small, and thermal efficiency is high.

(5) Clean emission: pulverized coal burner adopts air classification and low temperature combustion design, the temperature field is uniform, avoiding local high temperature combustion to generate large amount of NOx; the flue gas adopts lime desulfurization and bag filter, and the pollutant discharge concentration is low.

(6) Saving land: there is no coal yard and slag yard in the boiler room, and the floor space is small.

(7) High cost performance: low operating cost, the equipment investment can be recovered in a short time by saving coal.

Application:

DHS series pulverized coal fired steam boiler is widely used in chemical industry, paper making industry, textile industry, food industry, pharmaceuticals industry, heating industry, construction industry.

| Technical Data of DHS Pulverized Coal Fired Steam Boiler | |||||||

| Model | Rated Evaporation Capacity (t/h) | Rated Steam Pressure (MPa) | Rated Steam Temperature (°C) | Feed Water Temperature (°C) | Flue Gas Temperature (°C) | Fuel Consumption (kg/h) | Overall Dimension (mm) |

| DHS20-1.6-AIII | 20 | 1.6 | 204 | 105 | 145 | 2049 | 9800×7500×15500 |

| DHS30-1.6-AIII | 30 | 1.6 | 204 | 105 | 145 | 3109 | 11200×8000×17200 |

| DHS35-1.6-AIII | 35 | 1.6 | 204 | 105 | 145 | 3582 | 11700x8200x17800 |

| DHS40-1.6-AIII | 40 | 1.6 | 204 | 105 | 145 | 4059 | 12800x8900x17800 |

| DHS60-1.6-AIII | 60 | 1.6 | 204 | 105 | 145 | 6220 | 13310x10870x18200 |

| DHS75-1.6-AIII | 75 | 1.6 | 204 | 105 | 145 | 7170 | 13900x12600x19400 |

| Remark | 1. Design efficiency is 91%. 2. LHV is based on 26750KJ/Kg. | ||||||