News

-

What Are the Essential Parameters for Selecting an Industrial Gas-Fired Boiler?

Selecting an industrial gas-fired boiler is a strategic decision that significantly impacts operational efficiency, safety, and long-term energy costs. Making the wrong choice can lead to frequent breakdowns, high fuel expenses, and non-compliance with environmental standards. With today’s compl...Read more -

Large Capacity Modular Ultra-low NOx Gas Fired Hot Water Boiler

Gas fired hot water boiler with large capacity, high-efficiency and ultra-low NOx emission features capacity 46~70MW and pressure 1.6~2.45MPa. it adopts double drum longitudinal "D"-shaped single-layer layout. The gas fired hot water boiler includes radiant heating surface module, convection heat...Read more -

Taishan Won 33 Sets Coal CFB Boilers Order in Mongolia

Coal CFB Boilers are most popular coal boilers in the world. In June 2022, Taishan Group signed contract with Byucksan Engineering, and total contract value is over two hundred million Yuan. We are responsible for the boiler room system design and equipment supply of 9 capital cities in Mongolia....Read more -

Design of 130t/h Biomass CFB Boiler with Ultra-high Pressure and Reheat

130t/h Biomass CFB Boiler has the following main features: 1) The combustion temperature of the furnace is about 750°C, which can effectively prevent the fluidization failure due to low-temperature bonding of alkali metal-containing bed material. 2) High-efficiency cyclone separator ensures...Read more -

Optimization of Steam Air Preheater on Waste Incineration Boiler

Steam Air Preheater is replacing conventional flue gas air preheater in most waste incineration power plant boiler in China. There is large amount of acid gases like HCI and SO2 in the flue gas of waste incineration boiler, which can cause ash deposition and low-temperature corrosion in the tail ...Read more -

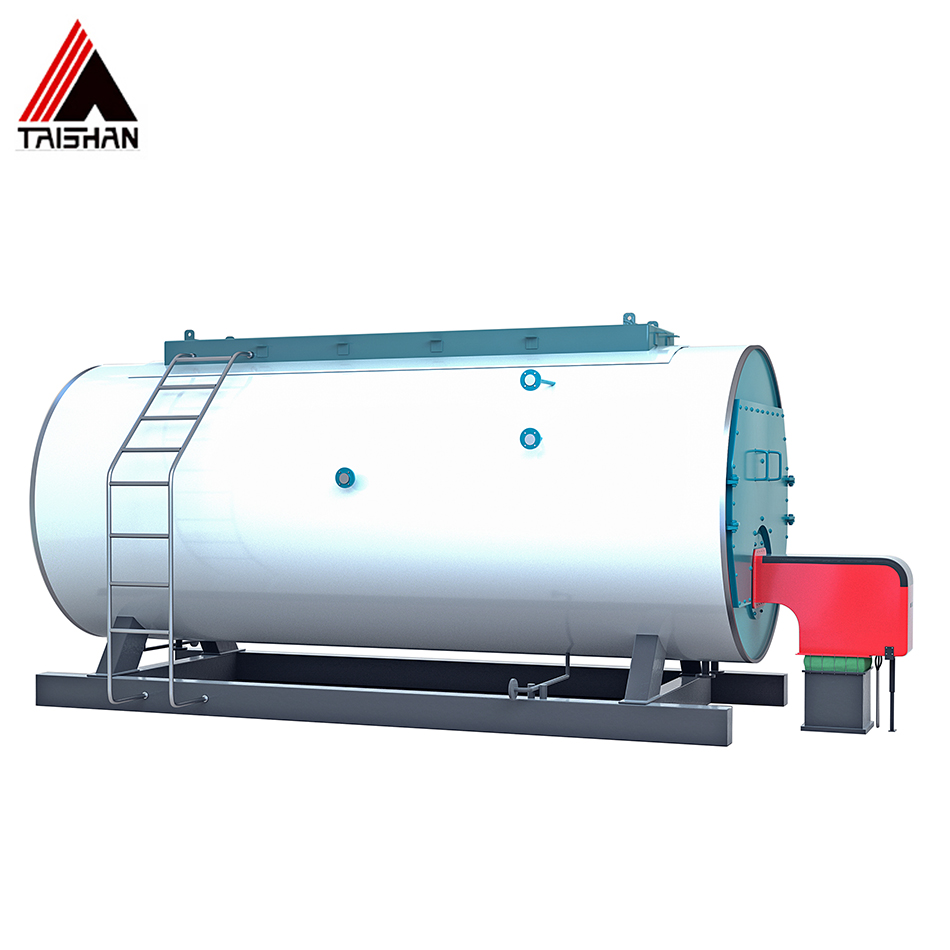

Design of WNS Superheated Steam Boiler

WNS Superheated Steam Boiler is full wet back three-pass shell boiler. The structure of oil/gas fired steam boilers includes water tube type and shell type. Water tube boiler has flexible heating surface arrangement, large heat capacity, strong load adaptability, and big occupation. Shell boilers...Read more -

Design of Small Capacity Coal Slurry Boiler

1. Introduction of Coal Slurry Boiler DHS15-7.5-J coal slurry boiler is a single drum natural circulation corner tube boiler. The boiler drum is outside and not heated, and the furnace adopts membrane wall. The evaporation heating surface is composed of flag surface, membrane wall and close pitch...Read more -

Technical Characteristics of Large Capacity MSW CFB Incinerator

CFB Incinerator is another type of waste incineration boiler besides grate incinerator. Circulating fluidized bed boiler has many advantages, such as high burnout rate, low carbon content in ash, wide load adjustment range, wide fuel adaptability. However, its operating cost is relatively high. I...Read more -

Biomass Fuels Boiler Design Proposal in Thailand

Biomass Fuels Boiler in Thailand mainly burns solid waste from agriculture and wood processing. Based on the low-carbon economy, power shortage and environmental pollution background, Thailand government made plans to develop clean renewable energy. This passage puts forward the ultimate analysis...Read more -

Comparison Between ASME Boiler Code and China Boiler Manufacturing License

S/N Main item ASME Boiler Code China Boiler Code & Standard 1 Boiler manufacturing qualification There are manufacturing authorization requirements, not administrative license: After obtaining ASME authorization certificate, the scope of authorized manufacturing is relatively wi...Read more -

Industrial Boiler Producer Was Awarded as Vice President of Taian ICC

Industrial Boiler Producer Taishan Group was awarded as the vice president of Taian International Chamber of Commerce on January 8. China Chamber of International Commerce (CCOIC) was founded in 1988. It is a national chamber of commerce composed of enterprises and other organizations engaged in ...Read more -

CFB Boiler Manufacturer Won Outstanding Contribution Award

CFB Boiler Manufacturer Taishan Group just won outstanding contribution award by its CFB boiler user GEM Company in December 2021. In December 2019, CFB Boiler Manufacturer Taishan Group won 1*75TPH Coal CFB Boiler EPC project in Tsingshan Industrial Park, Indonesia. However, due to the outbreak ...Read more